KVAL Commander Door Line

or

Call 704-288-1904

Specifications

| Manufacturer | KVAL |

| Model | Commander Door Line |

| Stock Number | 012276 |

Description

KVAL Commander Door Line

Manufacturer specs:

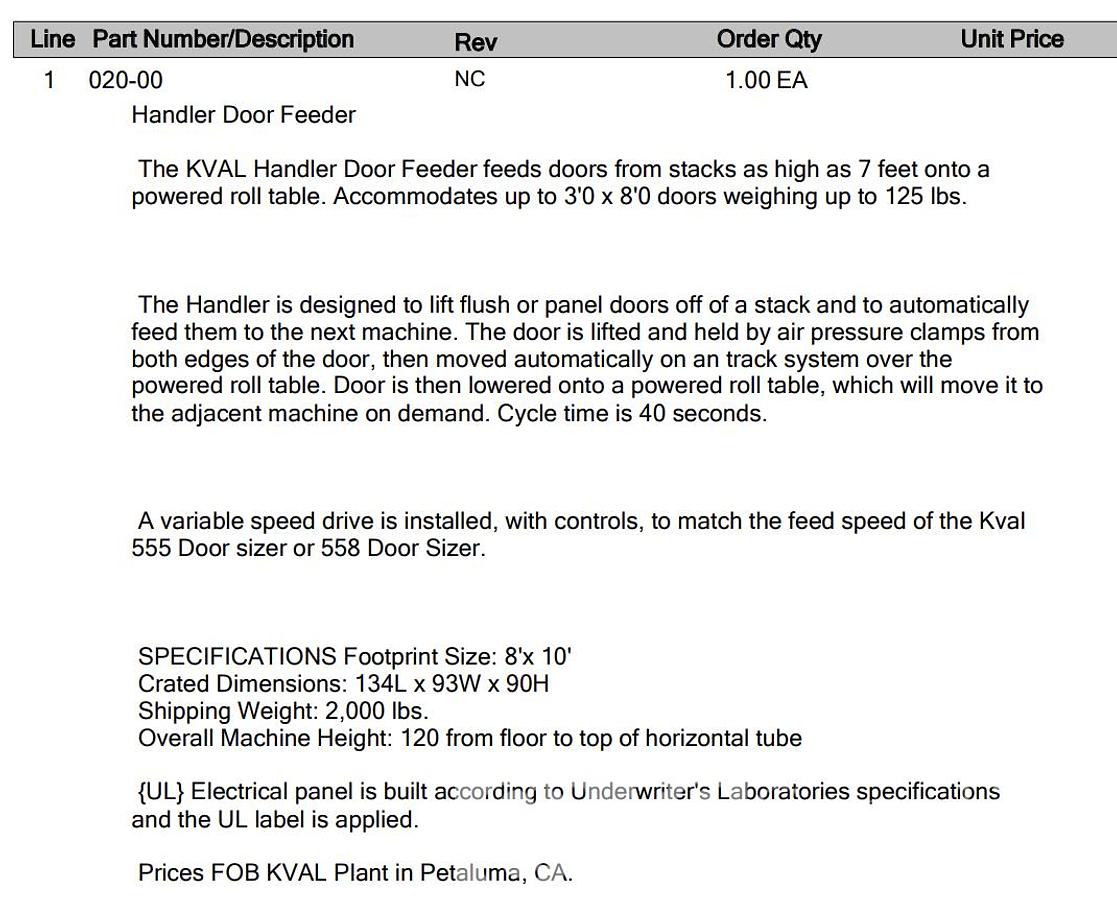

- Handler Door Feeder - The KVAL Handler Door Feeder feeds doors from stacks as high as 7 feet onto a powered roll table. Accommodates up to 3'0 x 8'0 doors weighing up to 125 lbs. The Handler is designed to lift flush or panel doors off of a stack and to automatically feed them to the next machine. The door is lifted and held by air pressure clamps fromboth edges of the door, then moved automatically on a track system over the powered roll table. Door is then lowered onto a powered roll table, which will move it tothe adjacent machine on demand. Cycle time is 40 seconds. A variable speed drive is installed, with controls, to match the feed speed of the Kval 555 Door sizer or 558 Door Sizer. SPECIFICATIONS Footprint Size: 8'x 10' Overall Machine Height: 120 from floor to top of horizontal tube

- COMMANDER OPTION H, PLUG-IN SHAFT WITH (4) COLLARS,TAPE, GLUE & INDEX POINTER FOR PRESET HINGE CENTER SET-UPS.

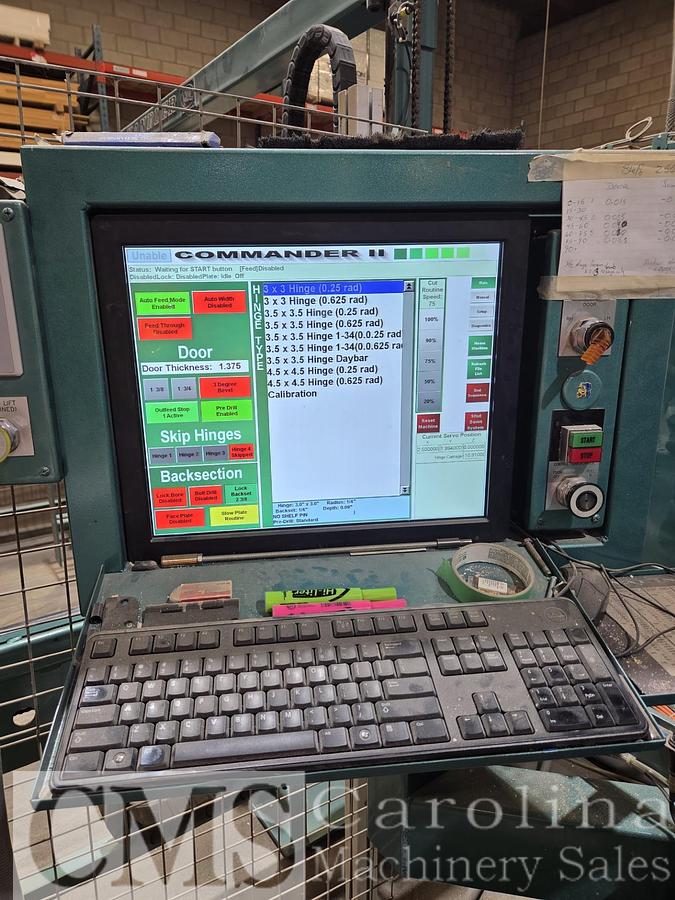

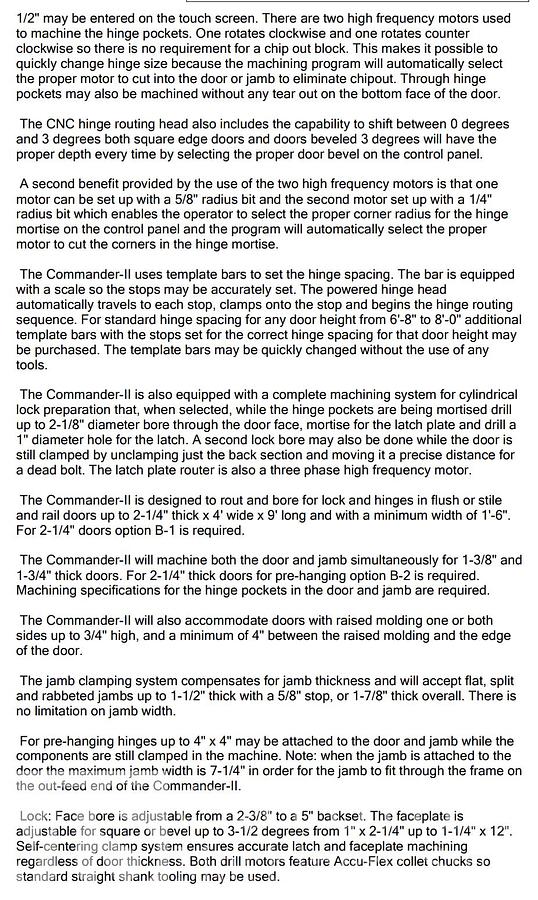

- 2012 Commander II The Commander-II is the latest version of KVALs best-selling and most flexible door machine. It is equipped with a completely CNC controlled hinge routing head. Hinge sizes that vary from 3" x 3" to 4-1/2" x 4-1/2" may be entered on the touch screen. There are two high frequency motors used to machine the hinge pockets. One rotates clockwise and one rotates counter clockwise so there is no requirement for a chip out block. This makes it possible to quickly change hinge size because the machining program will automatically select the proper motor to cut into the door or jamb to eliminate chipout. Through hinge pockets may also be machined without any tear out on the bottom face of the door. The CNC hinge routing head also includes the capability to shift between 0 degrees and 3 degrees both square edge doors and doors beveled 3 degrees will have the proper depth every time by selecting the proper door bevel on the control panel. A second benefit provided by the use of the two high frequency motors is that one motor can be set up with a 5/8" radius bit and the second motor set up with a 1/4" radius bit which enables the operator to select the proper corner radius for the hinge mortise on the control panel and the program will automatically select the proper motor to cut the corners in the hinge mortise. The Commander-II uses template bars to set the hinge spacing. The bar is equipped with a scale so the stops may be accurately set. The powered hinge head automatically travels to each stop, clamps onto the stop and begins the hinge routing sequence. For standard hinge spacing for any door height from 6'-8" to 8'-0" additional template bars with the stops set for the correct hinge spacing for that door height maybe purchased. The template bars may be quickly changed without the use of any tools. The Commander-II is also equipped with a complete machining system for cylindrical lock preparation that, when selected, while the hinge pockets are being mortised drill up to 2-1/8" diameter bore through the door face, mortise for the latch plate and drill a 1" diameter hole for the latch. A second lock bore may also be done while the door is still clamped by unclamping just the back section and moving it a precise distance for a dead bolt. The latch plate router is also a three phase high frequency motor. The Commander-II is designed to rout and bore for lock and hinges in flush or stile and rail doors up to 2-1/4" thick x 4' wide x 9' long and with a minimum width of 1'-6". For 2-1/4" doors option B-1 is required. The Commander-II will machine both the door and jamb simultaneously for 1-3/8" and1-3/4" thick doors. For 2-1/4" thick doors for pre-hanging option B-2 is required. Machining specifications for the hinge pockets in the door and jamb are required. The Commander-II will also accommodate doors with raised molding one or both sides up to 3/4" high, and a minimum of 4" between the raised molding and the edge of the door. The jamb clamping system compensates for jamb thickness and will accept flat, split and rabbeted jambs up to 1-1/2" thick with a 5/8" stop, or 1-7/8" thick overall. There is no limitation on jamb width. For pre-hanging hinges up to 4" x 4" may be attached to the door and jamb while the components are still clamped in the machine. Note: when the jamb is attached to the door the maximum jamb width is 7-1/4" in order for the jamb to fit through the frame on the out-feed end of the Commander-II. Lock: Face bore is adjustable from a 2-3/8" to a 5" backset. The faceplate is adjustable for square or bevel up to 3-1/2 degrees from 1" x 2-1/4" up to 1-1/4" x 12". Self-centering clamp system ensures accurate latch and faceplate machining regardless of door thickness. Both drill motors feature Accu-Flex collet chucks so standard straight shank tooling may be used.

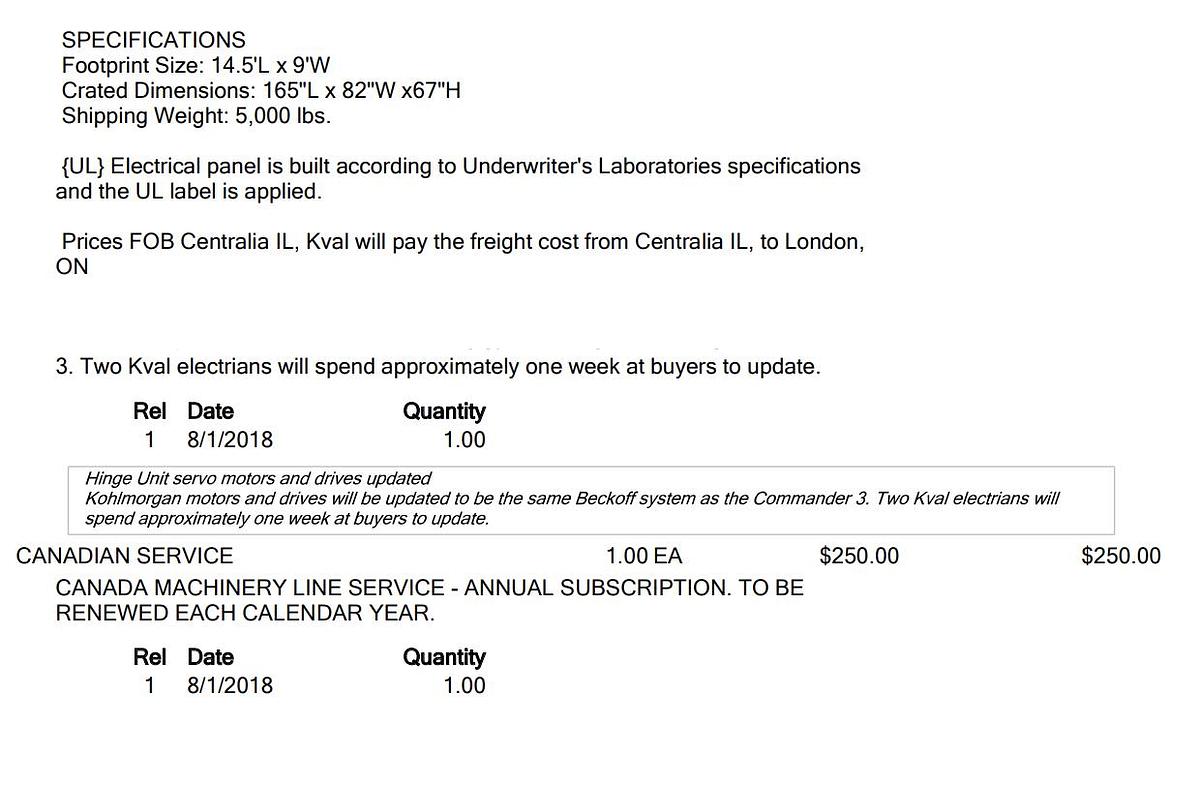

- SPECIFICATIONS: Footprint Size: 14.5'L x 9'W, Crated Dimensions: 165"L x 82"W x67"H Shipping Weight: 5,000 lbs.