2020 Homag Edgeteq S380 6.6 Edgebander

Specifications

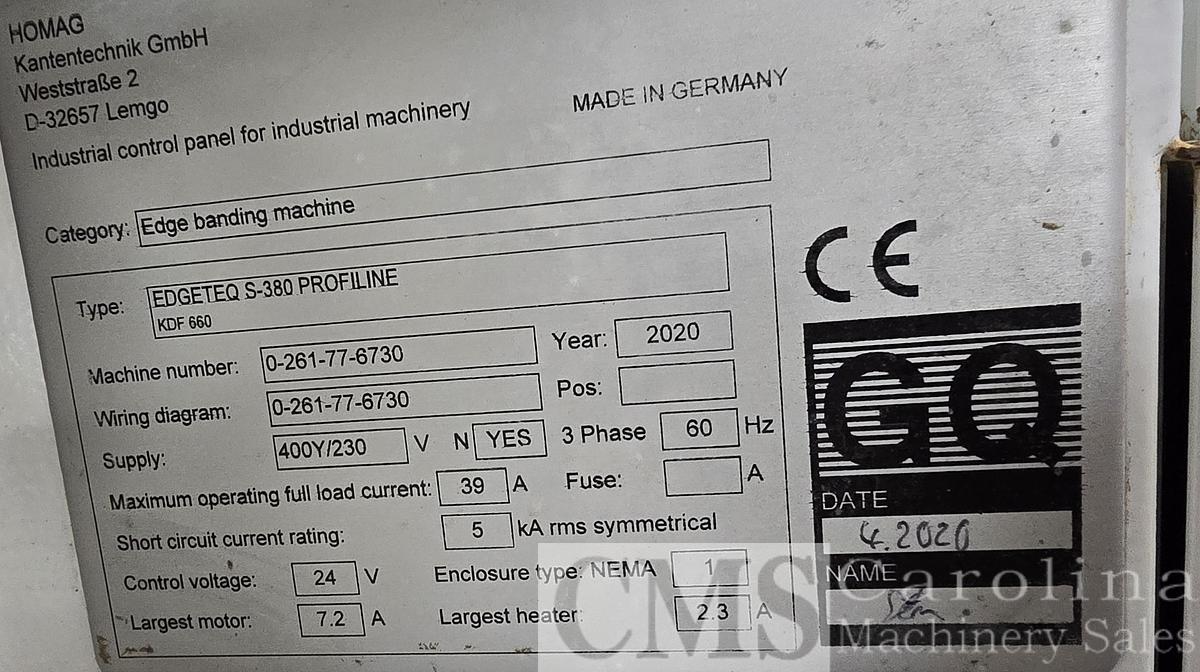

| Manufacturer | Homag |

| Model | Edgeteq S380 6.6 Edgebander |

| Year | 2020 |

| Stock Number | 011923 |

Description

Machine Features

● powerTouch Program Control

● Feed speed: 8 – 20 m/min

● electrical equipment installed according to UL regulations

● top pressure roller hold-down, motorized for workpiece thickness adjustment

● smooth upper pressure rollers

● automatic feed track lubrication system

● program-controlled infeed fence positioning

● automatic magazine for coil feeding from outside the machine

● workpiece gap optimization reduces spacing between parts to increase output

● Separating Spraying Unit

● Joint Trimming Unit for pre-trimming the workpiece edge prior to processing

Note:

The diamond cutter heads on this machine are only capable of processing a maximum workpiece thickness of 40 mm. Optional 60 mm tooling is available upon request.

● panel preheating zone five inches

● QA-65 N quick melt granulate glue application system with automatic purging function when using

EVA and PUR glues and sliding pre-melting unit

● quick change glue tank

● PUR Easy Melt Pre-melting unit for use with 2kg PUR glue slugs

● Lubrication spray unit on the last pressure zone roller for high gloss peel coat processing

● software pre-installation for anti-static unit

● infrared radiant quartz heating unit between glue roller and pressure zone for optimum gluing strength

● program-controlled positioning of the pressure zone. First pressure roller driven and three (3) idle pressure rollers

● Double-Motor End Trimming Unit with straight and chamfer capability. Chamfer up to 15 degrees.

Program-controlled indexing from straight to bevel end trimming

● MS 40 Multi-Stage Fine Trimming Unit with four (4) working positions: profile 1, profile 2, bevel, and flush trimming. Auto-tilt and servo control for edge thickness. Nested top copy system.

● MF 50 Multi-Functional Contour Trimming Unit for continuous trimming and profile corner trimming. Magnetic Linear Drive System with “soft touch” feature

● MZ 40 Multi-Stage Scraping Unit with program control for two (2) different radii with servo-controlled vertical and horizontal tracing. Nested top copy system.

Machine Features (continued)

● Finish Scraping Unit

● Detergent spray unit

● Buffing Unit with two (2) motors, two (2) cloth buffing discs (150 x 20 mm diameter)

● LOOPTEQ O-200 (TFU 120) Return Conveyor Connection Kit

● sound enclosure with centralized dust extraction outlet and internal LED lighting

● electronic frequency changer for all trimming motors

● isolation transformer with variable infeed voltage for balancing all three (3) phases of incoming power and increasing the lifetime of the machine’s electrical components

Technical Specifications

edgeband thickness:

COILS

0.4 – 3 mm

(1/64 – 1/8 in)

STRIPS

0.4 – 12 mm

(1/64 – 1/2 in)

material cross section:

MAX

PVC

135 mm2

VENEER

100 mm2

edgeband height:

12 – 65 mm

(1/2 – 2 1/2 in)

workpiece length:

MIN

160 mm

(6 1/4 in)

workpiece width:

MIN

70 mm

(2 3/4 in)

workpiece thickness:

8 – 60 mm

(5/16 – 2 3/8 in)

airTec

40 mm

(1 5/8 in)

feed speed:

8 – 20 m/min

(26 – 65 ft/min)

feed speed (with contour trimming):

14 m/min

(46 ft/min)

feed motor:

2.2 kW (3 HP)

pressure section:

one (1) driven roller, three (3) idle rollers

joint trimming unit (2x):

2.2 kW (3 HP) each / 12,000 rpm

end trimming unit (2x):

0.35 kW (1/2 HP) each / 12,000 rpm

fine trimming unit (2x):

0.55 kW (3/4 HP) each / 12,000 rpm

contour trimming unit (2x):

0.4 kW (1/2 HP) each / 12,000 rpm

total power required:

27 kW

amperage:

@ 230V

60 amps

@ 460V

30 amps

machine length:

6,273 mm

(20.5 ft)

machine width:

1,604 mm

(5.2 ft)

working height:

950 mm

(37 3/8 in)

total height (with hoods open):

2,266 mm

(7 1/2 ft)

machine weight:

2,940 kg

(6,481 lb)

electrical connection:

208/230/440/480V / 3-phase / 60 Hz

dust extraction:

(1x) 120 mm, (1x) 140 mm, (2x) 100, 2,048 CFM

machine compressed air:

15 CFM, 6 bar (87 PSI), 1/4” ID airline

Electrical equipment installed according to UL regulations.

Voltage supplied must not fluctuate in excess of ± 5% of its stated value. Voltage must be balanced phase-to-phase and phase-to-ground.

In case of incoming main voltage fluctuations of more than ± 5% of the machine connected voltage, a voltage stabalizer must be installed by the customer on the incoming power connection.

powerTouch Program Control

● operating panel with 22” FULL-HD multi-touch display in widescreen format

● utilizes standardized interface across all HOMAG Group machinery

● ergonomic touch operation with gestures such as zooming, scrolling and swiping

● simple navigation for standardized and intuitive operation

● intelligent display of readiness of production by light function

● Power Control V2

Top Pressure Roller Hold-Down, Motorized for Workpiece Thickness Adjustment

Separating Agent Spraying Unit

Joint Trimming Unit

● pre-trimming of the workpiece edge prior to gluing

● two (2) motors, 3 HP / each, 12,000 rpm

● one (1) motor clockwise rotation, one (1) motor counter-clockwise rotation

● vertical spindle adjustment via digital settings

● horizontal positioning via electro-pneumatic control

● dust extraction hood included with 120 mm diameter outlet

● diamond cutter heads

● 60 mm heads – salesorder 1379145

Automatic Magazine for Strip and Coil Feeding

● large coil table (800 mm diameter) with built-in rollers to allow for 3 mm PVC coils

● edge strip capacity: 0.4 – 12 mm

● auto coil feeding from outside the machine

● one (1) large driven pressure roller with pneumatic pressure control

● three (3) secondary rollers, all with controlled side pressure

● program-controlled setting of pressure zone

● strengthened pre-cutter for cutting thick PVC edges from the coil; maximum 3 x 45 mm; precutting system equipped with air volume reservoir for on-demand activation required for short workpieces

● Lubrication spray on the last pressure zone roller

Panel Pre-Heating

● Panel pre-heating zone prior to glue application

● 5” zone length for optimum panel heating

QA-65 N EVA Gluing Unit

● PUR and EVA glue processing including automatic purge cycle with gluing unit in the machine

● no lubrication required – uses a high tech bearing system

● pneumatic locking of the unit for gluing the last inch of the workpiece

● glue temperature indication of both pre-melting unit and glue roller via LED thermostat display visible to operator

● infrared radiant glue heat zone control for optimum gluing strength. Automatic temperature reduction if not run within 15 minutes. This feature reduces the temperature automatically by 50°C.

PUR Easy Melt Gluing System

● PUR pre-melter for 2kg PUR glue slugs

● PUR glue processing including automatic purge cycle of the QA-65 N gluing unit in the machine

● 5-minute heat up time for the pre-melter

● no lubrication required – uses a high tech bearing system

● pneumatic locking of the unit for gluing the last inch of the workpiece

● glue temperature indication of both pre-melting unit and glue roller via LED thermostat display visible to operator

● One 2 kg slug melting container is equipped with the machine

Sound Cover

● equipped with three (3) independent openings

● safety interlock system - when sound enclosure door is opened, corresponding work station shuts off

● end trimming, fine trimming, and top/bottom contour trimming motors are each equipped with electronic motor brakes to stop cutter rotation when hood is opened or when station is shut off at operator control panel

Software Pre-Installation for Spraying Units

Double-Motor End Trimming Unit

● straight / chamfer end trim unit equipped with two (2) 0.35 kW (1/2 HP) 12,000 rpm motors; electronic motor brakes

● program-controlled indexing from straight to bevel end trimming

● reduced spacing between parts for improved output

● end trim unit utilizes drawing cut system for reduced blade projection when working on thick workpieces

● tooling also included

MS 40 Multi-Stage Fine Trimming Unit

● equipped with two (2) 0.55 kw (3/4 HP) 12,000 rpm trimming motors

● electronic motor brakes

● horizontal and vertical tracing wheels

● nested top copy system

● auto-tilt feature

● servo motor-controlled positioning to edge thickness

● Four (4) profile choices: Profile 1, Profile 2, bevel, and Flush Trimming via program control

● equipped with two (2) multi-profile radius cutter heads, including four (4) knife carbide inserts

MF 50 Multi-Function Contour Trimming Unit for two radii

● dual purpose for corner rounding and or continuous trimming of top and bottom edge

● servo-controlled magnetic linear drive course of movement with “soft touch”

● includes two (2) trimming motors 0.4 kW (1/2 HP) 12,000 rpm; electronic motor brakes

● equipped with radius tooling, HSK 25 system, Impeller design for chip removal

● constant trimming speed for a perfect finish by means of synchronous motor RPM

● servo motor control of the cutter for edge thickness variation

● two position automatic indexing for both radii

● maximum feed speed: 14 m/min (46 ft/min)

● workpiece thickness: 12 – 60 mm

● minimum workpiece length: 160 mm

● maximum edge thickness: 3 mm

MZ 40 Multi-Stage Scraping Unit

● electro-pneumatic indexing in or out of position

● multi-profile for two (2) radii:

● servo-controlled positioning of both vertical and horizontal copy rollers

● nested top copy system

● multi-profile inserts are standard and included

Finish Scraping Unit

● flat knives remove any unwanted material from the trimmed / scraped edge

Top and Bottom Buffing Unit

● top and bottom buffing motors for finishing of longitudinal edges

● two (2) 2,800 rpm polishing motors

● inclinable vertically and horizontally

● two (2) buffing wheels included

LOOPTEQ O-200 (TFU 120) Return Conveyor Connection Kit

Software and wiring to link a TFU 120 return conveyor with the edgebanding machine. This integration provides operators with centralized control of both machines from the control panel of the edgebanding machine.

● feed speed and feed stop of return conveyor synchronized with edgebanding machine

● continuous control circuit allows any emergency stop to halt the entire production