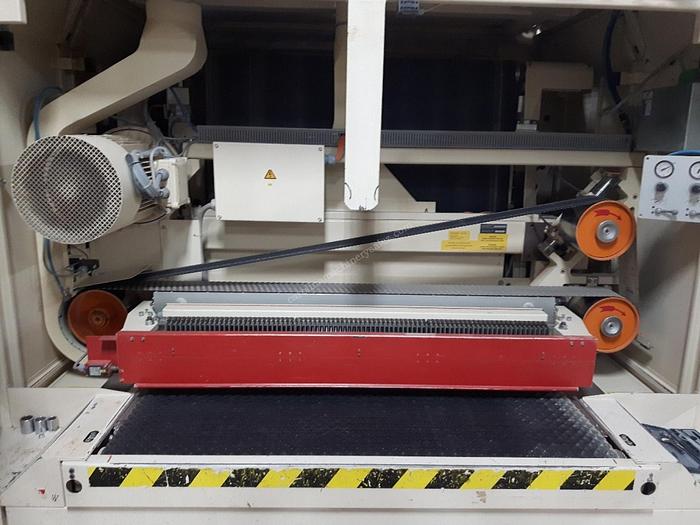

Heeseman MFA-8

Specifications

| Manufacturer | Heeseman |

| Model | MFA-8 |

| Stock Number | 008015 |

| Voltage | 575V, 60Hz, 3Ph |

Description

This machine has been removed from service and is ready to ship. 1 CROSS SANDING BELT & 1 LONGITUDINAL SANDING HEAD AND A WORKING WIDTH OF 1,300MM 1 Machine Frame arranged with conveyor unit with one single transport belt with ½” diamonds, feed speed adjustable within 5 - 25 m/min. by frequency control. Constant working height 880 mm, motor driven adjustment to various work piece thickness (3 - 140 mm) by height adjustment of the upper machine part, prepared for installation of 1 brush u Industrial PC Touch screen execution. Program Memory for 50 Programs data for feed and motor speeds, sanding stop, sanding intensity on the edges and sanding pressure are memorized and automatically set in accordance with the program selected. 1 Cross Sanding Unit Belt dimensions 4.800 x 150 mm Belt speed 4 + 12 + 24 m/s Drive power 4/12/17 kW Including belt blasting device, controlled depending on work piece, dis-connectable. 1 Longitudinal Sanding Unit Sanding belt dimensions 2.650 x 1.350 mm Belt speeds 0.5-12 + 20 m/s Drive power 11 / 17 kW Front Calibrating Return Roller Ø 110 mm for mild calibrating, un-grooved, activated from machine terminal, sanding grit compensation via operating terminal. 2 Pressure Beams with Computer Controlled Selective-Pressure-Regulation - System CSD® with Electromagnetic System (100% non pneumatic) Infinite pressure matching of individual pressure elements (pressure pads are interlinked) for optional multi-track feeding, 32 mm control roller spacing, work piece tolerance compensation up to a max. of 2 mm by maintenance-free lifting solenoids. Working width as well as sanding start and end of the pressure beam are controlled electronically. The pressure segments are driven by magnetic coils which are able to vary the force of each shoe stepless while a work piece passes the pressure beam. This innovative CSD® Technology always guarantees a proportional equal pressure according to the overlapping of the shoe and the work piece. The risk of sand through on the edges is nearly eliminated by this stepless, dynamic pressure control.