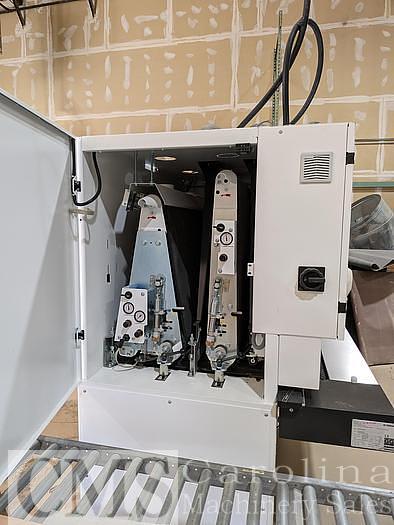

Homag Sandteq SWT100 43" 2-Head Sander

Specifications

| Manufacturer | Homag |

| Model | Sandteq SWT100 43" 2-Head Sander |

| Stock Number | 010806 |

Description

Homag SWT 100 series includes the following features:

Height Adjustment System – 100 Series

Conveyor bed is adjusted by four (4) large diameter dual supported threaded spindles

• Calibration sanding

• Veneer sanding

• Fine sanding of solid wood

• One machine for multiple sanding jobs

• Easy to use and quick setup times

• Automatic Star Delta starting

• Maintenance-free electrical main motor braking

• Electronic abrasive belt oscillation with photo eyes

• Pneumatic tensioning of abrasive belt

• Safety switch-off of machine during faulty operation

• Rubberized pressure rollers

• Workpiece thickness: 3 mm to 160 mm (1/8" to 6")

• Working width: 1100 mm (43")

• Abrasive belt width: 1120 mm (44")

• Abrasive belt length: 1900 mm (75")

• Abrasive belt changing side: left

Conveyor Drive System

Variable frequency-controlled feed speeds of 2.5 – 13 m/min. (18 – 42 ft/min.) with automatic

conveyor belt tracking and rubber drive roller

Touch Screen Display and Control

ECO Mode

Automatic machine stop with advance warning function for energy saving during idle time of the

machine.

Head 1: R Head - Steel Profiled Contact Roller Sanding Unit

This sanding head features a 140mm (5.5”) diameter profiled steel contact roller with automatic

positioning of the contact roller upon selection with integrated grit compensation. The steel

contact roller is ideal for calibration, providing optimal calibration sanding results:

Features & Details: HOMAG SANDTEQ W-124 RC (continued)

• 15.6" graphically supported color touch screen

• LCD-TFT color screen with 800 x 600 resolution

• Metric or decimal inch input (3 decimal places)

• 125 program memory

• Automatic machine control

• One-button start (Star Delta)

• Sequential motor starting

• Plain text error messaging at the operator terminal

• Program backup via USB stick possible

• Controls air or segmented pad options (only on models such feature)

• Manual head locking for fast abrasive belt changing

• Automatic Star Delta starting

• Maintenance-free electrical motor braking (no wearable parts)

• Grit compensation and automatic positioning for calibration

• Poly-V drive belt for maximum power and minimal vibration

• Non-contact photo eyes for abrasive belt oscillation

• Contact Roller (Steel): 140 mm (5.5”)

• Drive motor: 17.4 kW (23 hp)

• Belt speed: 18 mps (59 fps)

• Dust outlet size: 160 mm (6.5")

Head 2: C-Head – Combination Head Sanding Unit

This sanding head features a combination sanding head with an automatic positioning contact

roller with grit compensation as well as a segmented sanding pad for finish sanding. The

profiled rubber roller is ideal for light calibration or finish sanding while the segmented pad

provides performance versatility depending on the application:

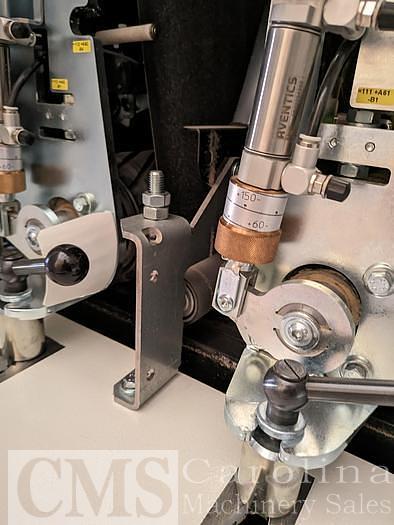

EPS Electro-Pneumatic Segmented Pad System (Head 2)

This head is equipped with an electro-pneumatic controlled segmented pad. This feature is

designed for precision sanding, with 35 mm pad resolution and sanding segments, particularly

well-suited for veneer segmented pad control is required

Air Jet Belt Blower (Head 2)

An air jet belt blower, activated by the workpiece:

Standard Accessories Kit

• Manual head locking for fast abrasive belt changing

• Automatic Star Delta starting

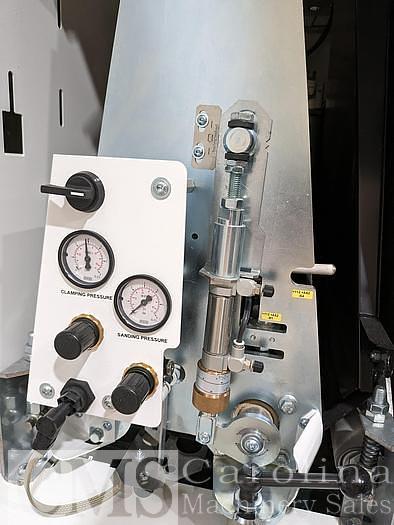

• Adjustable sanding pressures

• Maintenance-free electrical motor braking (no wearable parts)

• Grit compensation and automatic positioning for calibration

• Poly-V drive belt for maximum power and minimal vibration

• Non-contact photo eyes for abrasive belt oscillation

• Contact roller (Rubber) 140 mm - 60° (5.5”)

• Sanding element (pad): 80mm wide (0.52 felt)

• Drive motor: 12.88 kW (17 hp)

• Belt speed: 12 mps (39 fps)

• Dust outlet size: 160 mm (6.5")

• Application optimized for more effective cleaning results

• Programmable with five (5) intensity levels

• Keeps the belt cooler, extending the life of the abrasive belt

• No additional dust extraction is required for this feature

• Minor compressed air consumption required

• One (1) operator's manual

TECHNICAL SPECIFICATIONS

Voltage*: 460 Volts, 3 Phase, 60 HZ (24 V controls)

Full load amps: Approx. 63 FLA at 460 Volts

Compressed air**: 15 cfm @ 90 psi

Machine weight: ~4,000 lbs

*For estimating purposes only. Balanced phase-to-phase and phase-to-ground.

**Requires a minimum 3/4" supply line

Electrical connection: 460 volts. (230 volts on request with optional transformer)

Note: Switch Cabinet executed according to UL specifications but not UL approved.

DUST EXTRACTION @ 4500 FPM (FOR ESTIMATING PURPOSES ONLY)

Location Diameter

CFM

@ 3"

Static

Head 1: 160 mm (6-1/4") 850

Head 2: 160 mm (6-1/4") 850

Air Jet Belt Cleaner: 2x 100mm (4”) 700

Total CFM: 2,400

Recommended main size: 10"