2020 Cehisa Dynamic 9 C-Motion

Specifications

| Manufacturer | Cehisa |

| Model | Dynamic 9 C-Motion |

| Year | 2020 |

| Stock Number | 009559 |

Description

Pre-milling & Corner Rounding (EVA & PUR adhesive ready)

Basic Specifications:

Edgebanding material:

Melamine,

PVC,

Polyester,

Wood,

Laminate Strips --

Working speed:

Up to 14 m/min

Thickness of coil edgebanding:

0.4 –

3 mm,

Thickness of solid wood strips:

5 mm.

Thickness of panel:

10 – 60 mm.

Min. Length of panel:

120 mm. Min.

Width of panel:

75 mm

Features:

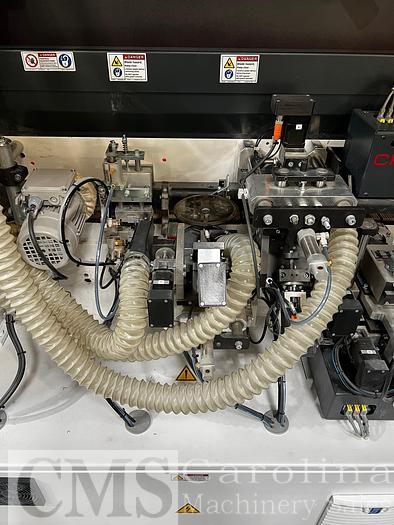

(18) Axes controlled with C-Motion Tech.

Automatic Infeed fence C-Motion Tech.

Pneumatic pressure rollers C-Motion Tech.

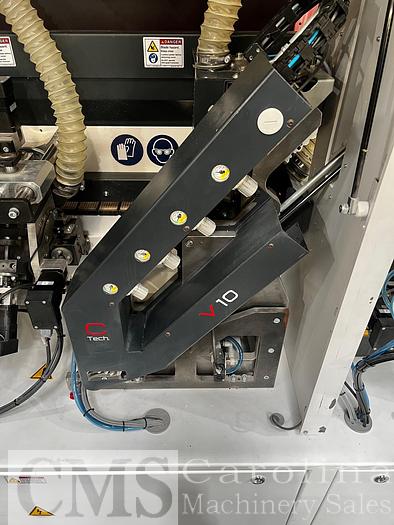

End trim unit (V-10N) with pneumatic tilting saws; 2 x HF.

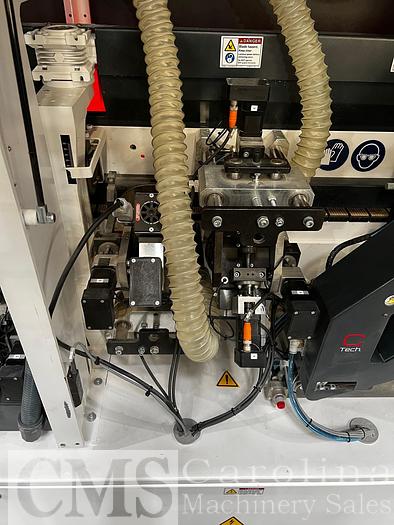

Trimming unit (BC-6M)

C-Motion Tech; Up to (6) controlled axes and multi-profile tools (up to 4 profiles).

Corner Rounding unit (CR-4M) C-Motion Tech; 2 x HF motors up to (4) controlled axes and quick change tool. Radius scraper (RB-9M) C-Motion Tech; Up to (6) controlled axes and multi-profile tools (up to 3 profiles). Motorized pressure beam with encoder and prismatic guides.

Automatic solid wood strips feeding system.

Connectivity Kit (machine control and technical assistance remotely).

C-Motion software with 10” color touch screen and pivoting supportWorkstations:

Pre-Milling PF-2 with 2 x HF motors - the first 1.1 kW, rotating CCW and the second 0.75 kW rotating CW, with pneumatic pressure control, providing optimum finish, New air blow nozzles for removing dust, Aluminum milling heads with interchangeable DIA cutters.

DUOMELT® Gluepot with DUOMELT® upgrade pack, allowing the use of the unit both with EVA and PUR adhesives; The pack includes a simple and efficient draining system for the residual glue in the glue pot and the necessary software to support this feature.

Pressure Rollers with (3) pneumatic pressure rollers exerting pressure on the edge band in order to achieve its adhesion onto the panel edge; The first roller is driven, and the second and the third ones are of smaller diameter and idle.

End Trimming V-10N with (2) independent motors HF (0.55 kW / 12,000 RPM) one performing the front and the other the rear trim cut, Smooth and precise movement of the carriage on two linear bearings along hardened and cylindrical base guideways. The saws can be tilted pneumatically at an angle 0 - 10° for a better finish of the end trim cuts.

Top & Bottom Trim Unit BC-6M with separate top and bottom units to trim the excess edging material along the upper and lower edges of the panel. High gloss tracers with SIKO digital readouts for easy and precise adjustment, (2) independent units, powered by HF motors 0,55 kW / 12,000 RPM, equipped with milling cutter heads for trimming solid wood edges up to 5 mm, roller high gloss tracers to work with 3D effect panels and edges, tooling: milling cutters with TC blades ø70 / ø20 x H20 Z4.

Corner Rounding CR-4M designed to round (4) corners of the panel edged with PVC/ABS band in order to achieve its complete finishing.