2020 Weinig Powermat 1500

Specifications

| Manufacturer | Weinig |

| Model | Powermat 1500 |

| Year | 2020 |

| Stock Number | 009128 |

Description

Weinig Powermatic 1500

This system was dropped and damaged during delivery. It will be sold as a parts machine. All motors and controls are new, never installed.

Specs from the manufacturer:

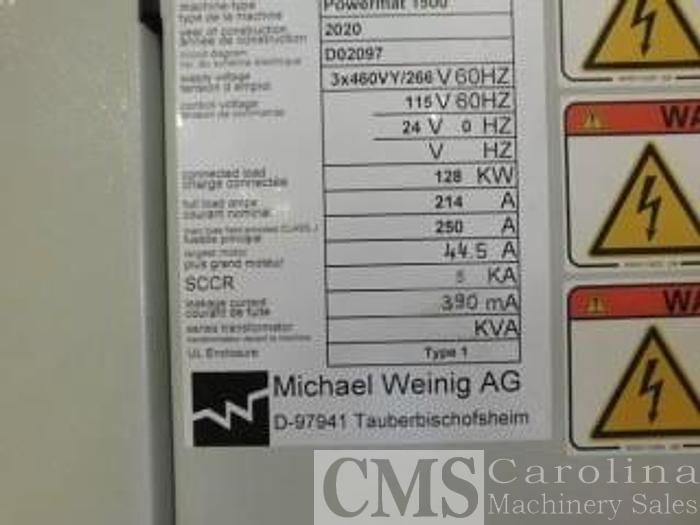

460 Volt, 60 Cycles

Tool arrangement no. 018 - BRLTTB

Working width 230 mm

FIRST BOTTOM: Motor 11 KW (15 HP) / 1 13/16" / 8000 rpm

WITHOUT rebate facility and WITHOUT rebate cutter / Digital radial adjustment

RIGHT VERT: Motor 11 KW (15 HP) / PLock / 4000- 12000 rpm

Pressure roller from above, pivoting, spring loaded

Axial / Radial CNC-controlled adjustment and positioning

LEFT VERT: Motor 11 KW (15 HP) / PLock / 4000- 12000 rpm

Vario hood (2 axes)

Pressure shoe in front, 2 lateral pressure rollers, spring-mounted

150 mm pendulum arbor extension

Pressure roller from above, pivoting, spring loaded

Axial / Radial CNC-controlled adjustment and positioning

FIRST TOP: Motor 22 KW (30 HP) / PLock / 4000- 12000 rpm

Vario Hood (2 axes)

Axial / Radial CNC-controlled adjustment and positioning

Prepared cassette system

SECOND TOP: Motor 30 KW (40 HP) / PLock / 4000- 12000 rpm

Vario hood (2 axes)

Axial / Radial CNC-controlled adjustment and positioning

Prepared cassette system

LAST BOTTOM: Motor 22 KW (30 HP) / PLock / 4000- 12000 rpm

Axial / Radial CNC-controlled adjustment and positioning

FEED SYSTEM: Motor 7 KW (9.5 HP)/ 5 - 40 m/min

Feed roller in front of 1st bottom spindle pneumatic "up-down"

CNC-controlled adjustment and positioning of feed up/down

Remote Lock out / Tag out

Switch cabinet and operating panel separate from machine

Cooling device for switch cabinet

Straightening table, 2 m long

Automatic Waxilit pump

Lateral pressure roller at the infeed table, spring-mounted

One 210mm driven roller in the machine table, hardened

One 210 mm driven roller in the outfeed table

Guiding fence after the left vertical spindle 8 mm thick, Pneumatic

PowerCom Plus

Improved sound insulation

Two additional interior lights in the safety hood