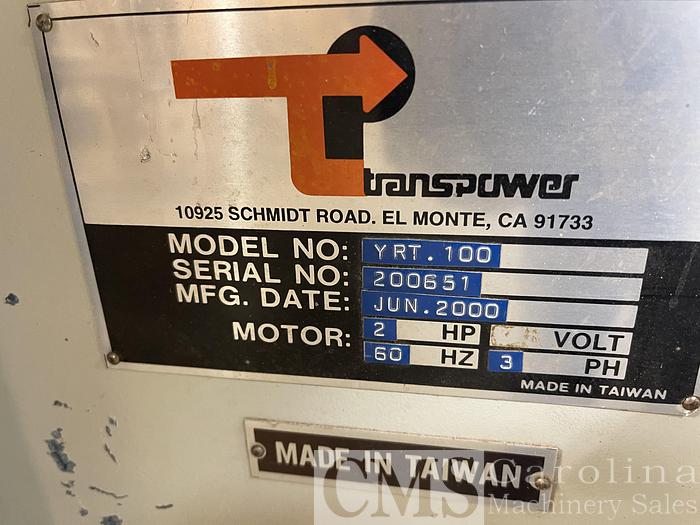

2000 Yow Cheng YRT 100 Mortise and Tenon Machine

Specifications

| Manufacturer | Yow Cheng |

| Model | YRT 100 Mortise and Tenon Machine |

| Year | 2000 |

| Stock Number | 009069 |

Description

This machine was used for one project by the seller. No longer needed for current applications.

MFG Specs (to be confirmed):

Double End Rectangular Tenoner (YRT-D100/D200)

Wrapped Workpiece Tenoning

The workpiece clamps at both sides are adjustable to suit workpiece wrapping condition.

This permits the machine to perform tenon cutting on a wrapped workpiece.

A Profitable Performer!

- Designed and engineered to help you upgrade competition edge and create profits.

- Capable to produce tenons at both ends simultaneously for greatly increasing tenoning efficiency.

- Fully automatic operation and automatic workpiece infeed and outfeed for effortless operations.

- Equipped with a high performance PLC control combined with touch sensing screen for easy learning and easy operation.

- Constructed with high quality parts for maximum dependability of performance year after year.

Outstanding Features:

- Equipped with a PLC control combined with touch sensing screen for user friendly operation.

- Fully automatic tenoning operation greatly upgrades production output.

- Cutting tenons at both ends simultaneously for greatly increasing efficiency and productivity.

- Designed for producing rectangular and cylindrical tenons.

- The machine is suitable for producing horizontal, vertical and mitered tenons.

- Cutter feed speed is controlled by frequency inverter, allowing for variable speed change.

- Equipped with a workpiece magazine for fully automatic operation.

- Workpiece feed slide ways are equipped with precision linear motion guides, ensuring fast and stable feed motions.

Convenient Tenon Width Adjustment

Tenon width adjustment is conveniently made by simply turning the adjustment knob.

A mechanical meter is equipped for accurately indicating the width adjustment amount.

Workpiece Magazine

A magazine is equipped at front of the machine.

Operator simply places workpieces into the magazine.

Then the machine will automatically perform workpiece feeding and tenon cutting.

This provides maximum operation convenience and upgrades productivity.

The finished products will automatically outfeed to the product rest, permitting operators to take products with ease.

User-Friendly Control

The machine is equipped with a PLC for controlling the entire motion sequences.

It combines with touch sensing screen, providing maximum operation convenience.

An Amp.meter is provided on the control panel for indicating the loading condition on main motors.

The controller provides major functions as below:

- Chinese/English display conversion

- Selection of operation mode as manual, automatic, semi-automatic and fully automatic

- Malfunction indication

- Timing display

- Production quantity setting and display

Smooth Feed Motion

The workpiece feed slide ways are equipped with precision linear motion guides, providing fast and extremely smooth feed motions.

Feed carriages at both sides are transmitted by a single shaft, ensuring synchronized travel.